Table of Contents

ToggleStrike plates as the anchor of the lock

On every hinged door, the lock does not protect anything by itself.

The bolt needs solid material in the frame to bite into, and that job falls to the strike plate.

For small businesses, upgrading the strike plate often creates more real security than changing the handle or adding a second lock.

A reinforced plate with long screws helps the frame stand up to kicks, prying, and day to day abuse.

How force travels through the door frame

When someone forces a door, the weakest part usually fails first.

On many doors, that weak point is the short section of wood around a small, light duty strike.

A stronger plate spreads force over a wider area of the jamb.

Long screws reach deeper into the framing, so the bolt works with the structure, not just with a thin trim piece.

This path of force matters more than the appearance of the trim or the style of the lever.

Features of reinforced strike plates

Reinforced plates differ from basic residential strikes in more than thickness.

A good security strike typically offers three improvements.

- Extended length so the bolt engages across more of the frame

- Heavier gauge steel or other robust metal to resist deformation

- Screw holes positioned so fasteners reach the wall framing, not just the jamb skin

Some designs include wraparound or box features that support the bolt pocket.

On commercial openings, you may see strikes that pair with latch guards and continuous hinges as part of a full security package.

Choosing strike plates for common door setups

Different doors and lock types call for different strike designs.

Matching the plate to the hardware keeps the door operating smoothly and improves security.

For latch sets and cylindrical locks, use strikes that match the latch type and backset.

For deadbolts, choose plates with full depth bolt pockets and enough metal around the cutout.

On metal frames, work with strikes and dust boxes built for the profile of the frame.

On timber frames, extended security strikes with long screws often provide the best improvement for the least cost.

Glass storefront doors and aluminum frames may rely on specialized strikes or electric strikes integrated with access control.

In these cases, strike selection must account for both mechanical strength and the needs of readers, cylinders, or electronic housings.

Installation steps for stronger anti prying performance

Even a heavy strike underperforms if someone installs it carelessly.

A simple, careful process makes a big difference.

First, check alignment between latch or bolt and the existing strike opening.

The door should latch or deadbolt without lifting, pushing, or slamming.

Next, prepare the frame for the new plate.

If you upgrade from a small strike to a longer reinforced version, extend the mortise cleanly so the plate sits flat and tight.

Then, use long screws where the design allows.

Aim for screws that reach into the wall stud or structural member, not just the face of the jamb.

Finally, test operation with the door open and closed.

The bolt should fully extend into the strike without rubbing heavily on the sides, and the door should close and seal correctly.

Mistakes that weaken even good strike plates

Many doors with upgraded strikes still fail early because of avoidable errors.

Watching for a few common problems helps keep your investment effective.

Short screws in oversized holes reduce the value of a reinforced plate.

If a screw does not reach solid framing, the plate may tear away under load.

Overcut mortises leave thin wood around the strike area, which can split under impact.

Keeping the mortise tight and using backing where needed protects the frame.

Misalignment between deadbolt and strike causes partial engagement.

A bolt that only enters halfway into the pocket cannot deliver full strength, even with a heavy plate.

Ignoring the rest of the opening also creates risk.

A strong strike helps, yet hollow doors, weak hinges, or unprotected glass panels can still offer easier attack paths.

Where EOS SECURE cylinders fit in the system

Strike plates work together with cylinders, locks, hinges, and doors as one system.

EOS SECURE focuses on the cylinder and locking components that control the bolt at the door edge.

When a high quality cylinder drives a well installed deadbolt into a reinforced strike, the opening gains real resistance to common attacks.

In projects that move toward smart access, EOS SECURE mechanical strength still supports electronic cylinders, readers, and advanced keying.

FAQ

What does the strike plate do

The strike plate covers and reinforces the hole in the frame where the latch or deadbolt enters. It guides the bolt into position and helps spread force from the lock into the surrounding structure. A stronger strike plate improves how the door resists kicking and prying.

What is a strike plate on a car

On a car door, the striker or latch plate is the fixed piece on the body that the door latch grabs when you close the door. It aligns the latch and keeps the door firmly shut. Although the design differs from building doors, the idea is similar, a moving latch engages a fixed plate.

What strike plate do I need

The right strike plate depends on your lock type, door material, and security level. Match the plate to the latch or deadbolt and the frame profile, then look for reinforced or extended plates with long screws on exterior or high risk doors. When in doubt, a locksmith or hardware specialist can review the opening and recommend a suitable model.

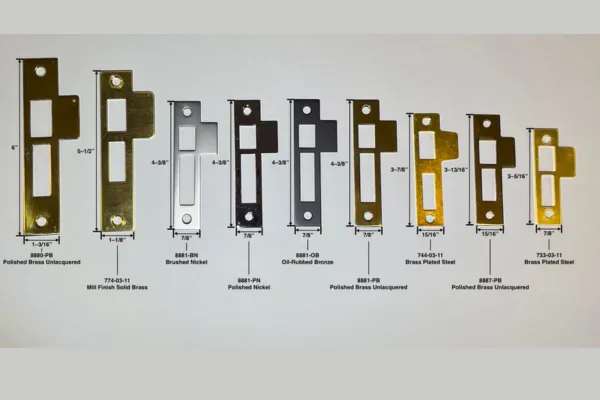

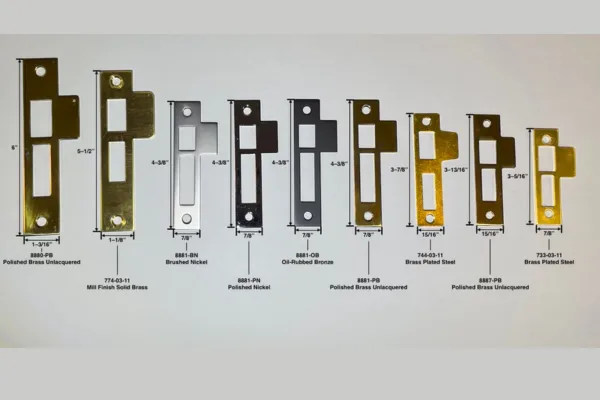

What are the different types of strike plates

Common types include standard latch strikes, deadbolt strikes with deeper pockets, full lip and T strike styles, and heavy duty security strikes that extend further along the frame. Electric strikes add a moving component that works with access control. Each style matches specific lock bodies and door constructions.

What does wrapping a rubber band around your doorknob mean

People sometimes wrap a rubber band around a knob or lever to hold the latch back or soften noise when the door closes. It can help during short term moving or frequent trips through a doorway. It does not improve security and should not replace a properly latching lock and correctly adjusted hardware.

Where are kickplates required

Building codes and standards vary, yet many commercial spaces use kick plates on doors exposed to carts, luggage, or frequent impact. They protect the lower part of the door from dents and scratches. Requirements can appear in project specifications, accessibility guidelines, or facility standards.

Are kick plates worth it

Kick plates often pay off on busy doors because they extend the life of the door surface. They take the abuse from foot traffic and equipment instead of the door face. For small businesses, a simple stainless or durable kick plate can reduce repair and repainting costs over time.

About EOS SECURE

EOS SECURE delivers precision engineered mechanical and electronic lock cylinders backed by more than a decade of manufacturing expertise. Established in 2011, our factory operates under ISO9001 and ISO14001 certifications, and our products meet rigorous international standards including EN1303 and SKG. With more than 50 advanced Swiss type CNC automatic lathes and integrated machining centers, we manufacture high quality cylinders and locking components that pair effectively with reinforced strike plates and commercial door hardware. Whether you need cylinders for high security deadbolts, smart access upgrades, or large scale production, EOS SECURE provides reliable performance, consistent quality, and dependable technical support. Secure your business with solutions built for long term stability, contact us today.