Table of Contents

TogglePrecision machining as the hidden strength behind every cylinder

When a key turns cleanly in a lock, that feeling comes from metal parts you rarely see.

Pins, plugs, and housings line up within microns so the cylinder responds quickly instead of grinding or catching.

For EOS SECURE and other serious manufacturers, precision machining does more than improve feel.

It supports long service life and raises the effort required for drilling, snapping, and other forced attacks.

A walk through a precision cylinder line

Imagine a cylinder body at the start of production.

It begins as bar stock, moves through several machines, then leaves the line as a finished core ready for keying.

Each station adds accuracy

- Turning stations set outer diameters and reference faces

- Drilling and boring create central bores for plugs

- Milling centers cut keyways, cam features, and fixing details

At every step, cutting tools follow programmed paths so dimensions stay within tight limits across thousands of parts.

How precision affects the way a key feels

Lock owners notice quality first at the keyway.

Fast, rough machining creates burrs and irregular edges that scratch keys and collect debris.

Precision machining shapes the keyway so

- The key glides in with steady resistance

- Teeth engage pins in a predictable sequence

- The plug turns without side wobble

That controlled movement gives locksmiths better feedback when they key or service cylinders, and it gives users a firm sense of quality every time they unlock a door.

Geometry that supports anti picking behavior

Security features start with drawings, yet they only work if machining respects the details.

Pin chambers, plug shoulders, and keyways all influence how a cylinder reacts when someone applies torque and probing tools.

Tight control over pin hole spacing keeps stacks aligned.

Careful selection of diameters and clearances limits unwanted movement inside the plug.

In higher security designs, precision machining also positions

- Sidebars and secondary locking elements

- Hardened inserts that block direct drilling

- Complex keyway curves that guide key movement

When these parts sit exactly where designers intended, attack tools face less free play and fewer easy attack paths.

Tolerance control and long term reliability

Doors in real buildings see dirt, temperature swings, and thousands of cycles.

A cylinder that leaves the factory only barely within tolerance may work on day one yet degrade quickly under those conditions.

Good machining practice treats tolerance as a window, not a target edge.

Production keeps critical dimensions comfortably inside the limits so wear, plating thickness, and small impacts do not push the part out of range.

This approach helps

- Maintain smooth operation over many years

- Keep master key systems stable as pins and plugs age

- Reduce callouts for sticking or inconsistent locks

For a property manager, those benefits show up as fewer complaints and lower service cost per door.

Machines, tools, and materials working together

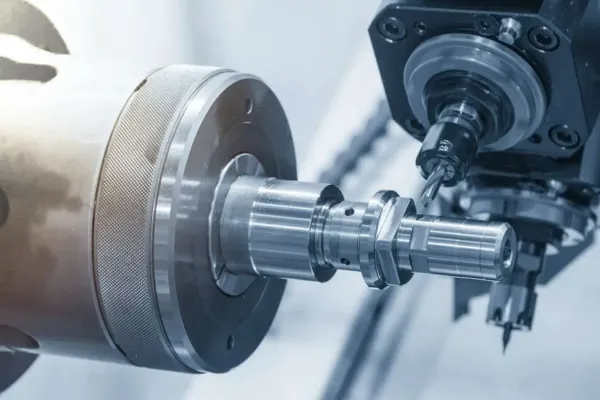

Precision machining depends on three elements that support each other, the machine, the tool, and the metal.

Swiss type CNC automatic lathes handle small diameter work with excellent repeatability.

Integrated machining centers then add side features and complex geometries in single setups.

Tooling choices match the material and geometry of each cylinder family.

Sharp, stable tools limit heat and vibration, which helps parts keep shape during and after cutting.

Materials such as brass and hardened alloys provide a balance of machinability, strength, and corrosion resistance.

When machines, tools, and materials align, cylinders leave the line with consistent fit and finish.

Verification that links machining to real security

Measurement closes the gap between theory and performance.

Metrology teams check more than just one sample from a new program.

They use

- Gauges for diameters and lengths on plugs and housings

- Microscopes and optical tools for keyway and pin seat geometry

- Functional tests with sample keys and pin stacks

In security ranges, destructive tests and simulated attacks confirm that drilled features, hardened elements, and break points behave correctly.

That feedback returns to programming and tool selection so the next batch performs even better.

Why precision machining matters to buyers and specifiers

Most buyers compare lock products through catalogs and brochures.

Precision machining never appears as a single line item, yet it influences almost every user facing result.

For distributors and locksmiths

- Cylinders from a precise line key more quickly

- Replacement parts fit without adjustment

- Warranty claims drop as operational problems decrease

For building owners and security consultants

- Doors stay reliable under heavy traffic and varied climates

- Key systems remain stable so policies work as planned

- Anti drill and anti pry features deliver the performance described in specifications

Choosing manufacturers that invest in precision machining gives projects a stronger mechanical base for both mechanical and electronic locking.

FAQ

What is precision in machining

Precision in machining describes how closely finished parts match their intended dimensions and shapes across many pieces. It focuses on tight, repeatable tolerances. In lock work, higher precision leads to smoother cylinders, better durability, and more consistent security behavior.

What is the meaning of precision machine

A precision machine is equipment designed to cut or shape parts with very small dimensional variation. It controls motion, speed, and cutting forces carefully. When programmed and maintained well, it produces components that meet demanding fits and functional requirements.

What do precision machinists do

Precision machinists set up and run machines that create high accuracy parts. They read drawings, program or adjust CNC controls, choose tools, and measure results. Their work ensures components such as lock cylinders meet both mechanical standards and security expectations.

What is precision metal machining

Precision metal machining means shaping metal parts with controlled cutting processes and tight tolerances. It can involve turning, milling, drilling, grinding, and related operations. In cylinder manufacturing, this approach keeps keyways, pin chambers, and plug fits accurate.

Do CNC machinists make a lot of money

Earnings for CNC machinists depend on skill, responsibility, industry, and region. Those who program complex jobs, hold tight tolerances, and support high value products often earn more than entry level operators. Experience with troubleshooting and process improvement also increases pay potential.

Is precision machining hard

Precision machining demands focus and a solid technical base. Machinists manage tools, materials, heat, and vibration while holding small tolerances. Training and practice make the work manageable, yet the field continues to reward people who enjoy careful work and continuous learning.

What is the highest paying machining job

Higher paying roles often include CNC programmers, toolmakers, process engineers, and specialists in aerospace, medical, or other demanding sectors. Supervisory positions and advanced field service roles that support complex machinery can also reach the top end of machining pay scales.

What is the mother of all machines

Many people describe the milling machine as the mother of all machines because it can create flat surfaces, slots, gears, and even parts for other machines. Modern machining centers expand on this idea by combining milling, drilling, and sometimes turning in one flexible platform.

About EOS SECURE

EOS SECURE delivers precision engineered mechanical and electronic lock cylinders backed by more than a decade of manufacturing expertise. Established in 2011, the factory operates under ISO9001 and ISO14001 certifications, and products meet rigorous international standards including EN1303 and SKG. With more than 50 advanced Swiss type CNC automatic lathes and integrated machining centers, EOS SECURE applies precision machining to every cylinder family so key systems stay smooth, reliable, and secure over long service lives. Whether you need restricted key systems, electronic ready cores, or large commercial runs, EOS SECURE provides dependable performance, consistent quality, and technical support you can trust. Secure your business with solutions built for long term stability, contact us today.