Table of Contents

ToggleLock cylinders as the core of every locking system

At every secure door you will find one small part that decides who can enter, the lock cylinder.

Keys, handles, smart readers, and heavy bolts all rely on that cylinder to translate a credential into motion at the latch.

When you understand cylinder types, security levels, and replacement steps, you can choose hardware that fits both today’s needs and future upgrades instead of guessing at the counter.

Main lock cylinder formats in commercial doors

Different door standards and regions favor different cylinder bodies.

Each format shapes how you design master key systems and how you plan replacements.

Euro profile cylinders

Euro profile cylinders appear widely on aluminum, uPVC, and many modern timber doors.

They use the familiar double ended shape with a cam in the middle that drives the lock case.

Common options include

- Double cylinders, key both sides

- Single cylinders, key one side and thumbturn inside

- Half cylinders, for applications such as roller shutters or machine enclosures

For security projects, focus on correct length, anti snap features where needed, and cylinders tested to relevant European standards.

Rim and mortise cylinders

Rim cylinders sit on the surface side of the door and connect through a tailpiece to night latches or exit devices.

They offer an easy way to control locks that already bolt onto the inside of the leaf.

Mortise cylinders thread or secure into mortise lock bodies inside the door edge.

They give a clean look with strong mechanical support and appear in many commercial timber and metal doors.

Both styles let you rekey or upgrade cylinders while leaving the main lock case in place.

Key in knob and lever cylinders

Many cylindrical locks on interior doors use small plug style cylinders hidden inside knobs or levers.

You remove the trim, slide out the cylinder, and replace or rekey it without changing the whole lockset.

These cylinders often form part of large master key systems in offices, schools, and light commercial buildings.

Interchangeable core formats

Small Format Interchangeable Cores and Large Format Interchangeable Cores support rapid changes with a control key.

Security teams pop cores in and out while the housings stay mounted in the lock.

This approach suits hospitals, campuses, and multi site portfolios where rekey work happens often and downtime must stay low.

How cylinder security levels differ

Not every cylinder offers the same protection, even if the outside looks similar.

Security levels come from both mechanical design and the way you control keys.

Resistance to forced attacks

Look for features such as

- Hardened inserts that slow drilling

- Anti snap and anti pull designs on exposed euro cylinders

- Strong keyways and plug supports that resist wrenching

The best results come when you pair strong cylinders with reinforced strikes, solid frames, and good hinges, so force spreads through the whole opening instead of one weak point.

Protection against picking and bumping

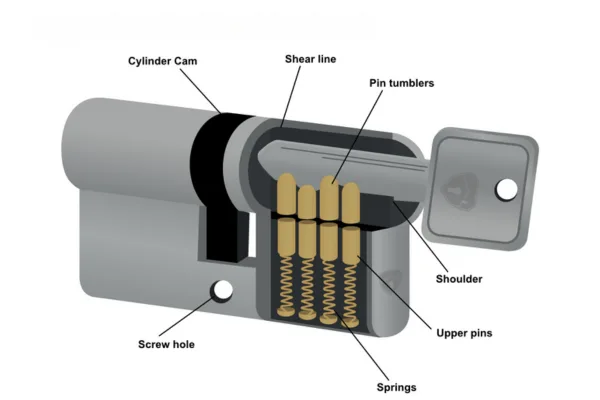

Cylinder internals matter just as much as outer armor.

Higher grade designs may use

- Complex pin stacks or additional elements

- Tighter tolerances that make manipulation harder

- Patented keyways that limit access to blank keys

No cylinder can promise absolute protection, yet stronger designs raise the skill and time required for a successful attack.

Key control and duplication rules

Real world security often fails at the key counter.

If anyone can copy a key without checks, even a high end cylinder loses much of its advantage.

Controlled or restricted key systems use

- Patented key designs with registered duplication rights

- Tracked key cutting at authorized centers

- Clear records of who holds each level of key

For EOS SECURE and similar platforms, cylinder security and key control work together, mechanical strength on the door and administrative strength in your processes.

Typical reasons to replace a lock cylinder

Knowing when to change cylinders helps you protect security without overspending.

Common triggers include

- Lost, stolen, or unreturned keys

- Tenant changes or staff turnover in key positions

- Damage from wear, vandalism, or previous attacks

- Moves to new key systems or higher security standards

- Upgrades from pure mechanical to electronic cylinders

In some cases, you can rekey within the same hardware family rather than replace the full cylinder.

In others, a complete cylinder change gives a better path toward modern security features.

Step by step overview of cylinder replacement

Exact steps depend on the lock type and local codes, yet most cylinder changes follow the same pattern.

First, plan the new cylinder.

Confirm format, length, finish, keyway, and any master key or electronic requirements before you touch the door.

Next, remove existing trim or screws.

On euro cylinders, you loosen the fixing screw at the edge of the door, then turn the key slightly and slide the cylinder out.

On rim or mortise cylinders, you remove the outer ring and any mounting screws, then withdraw the cylinder carefully.

Then, fit the new cylinder.

Align the cam or tailpiece with the lock case, seat the cylinder fully, and secure it with the correct screws and collars.

Check that the cylinder does not project more than the standard allows, especially on exposed exterior doors.

Finally, test function with the door open and closed.

Keys should turn smoothly, the latch or bolt should throw and retract fully, and any thumbturns should operate without binding.

For fire rated and escape route doors, follow manufacturer instructions and local regulations, since incorrect hardware can affect certifications.

Quick selection checklist for small business owners

When you choose cylinders for a new project or an upgrade, run through a simple checklist.

- Door type, material, and traffic level

- Required cylinder format, euro, rim, mortise, key in lever, SFIC, or LFIC

- Security grade and any regional standards

- Key control expectations, open keys or restricted system

- Future needs, such as electronic cylinders or integration with access control

This list keeps conversations with suppliers focused on function and risk instead of only on price.

It also helps you build a hardware schedule that can grow with your business rather than hold it back.

FAQ

What is a lock cylinder used for

A lock cylinder houses the keyway and internal components that read the key. It converts the correct key turn into movement of the latch or bolt, so it acts as the decision point between the user and the mechanical parts of the lock.

What is the meaning of cylinder lock

A cylinder lock is a lock that uses a removable cylinder as its core. The cylinder contains the plug and pins that match the key, while the main lock body stays on the door. This design allows rekeying or replacement without changing the entire lockset.

What is a cylinder lockset

A cylinder lockset is a complete door lock assembly built around a key driven cylinder. It includes the cylinder, latch or bolt, outside and inside trim, and any related hardware. The cylinder lockset lets you control access with a key while providing a finished look and reliable operation on the door.

What is a keyless lock

A keyless lock lets users unlock a door without a traditional metal key. It may rely on PIN codes, cards, fobs, mobile credentials, or a mix of methods. Many keyless locks still include a cylinder for backup or for integration with existing key systems.

What are the three types of cylinders

People often group cylinders into three broad types, euro profile cylinders, rim or mortise cylinders, and key in knob or interchangeable core cylinders. Each type fits different lock bodies and door constructions and each supports its own keying and security options.

How much does a lock cylinder replacement cost

Costs depend on cylinder type, security level, and labor in your region. Basic cylinders with open keyways cost less, high security or restricted systems cost more. Total cost includes both the cylinder and the time to remove old hardware, fit the new cylinder, and manage key changes.

Can cylinder locks be picked easily

Simple low cost cylinders can be vulnerable to picking and other manipulation. Higher security models use more complex pinning, tighter tolerances, and protective features that slow attacks. No cylinder is impossible to pick, yet stronger designs and good installation raise the effort required.

What is the most common cylinder lock

In many commercial and residential markets, pin tumbler cylinders are the most common type. They appear in euro profiles, rim and mortise cylinders, and many key in knob designs. Their popularity comes from a balance of cost, durability, and support for master key systems.

About EOS SECURE

EOS SECURE delivers precision engineered mechanical and electronic lock cylinders backed by more than a decade of manufacturing expertise. Established in 2011, our factory operates under ISO9001 and ISO14001 certifications and our products meet rigorous international standards including EN1303 and SKG. With more than 50 advanced Swiss type CNC automatic lathes and integrated machining centers, we manufacture high quality cylinders in a wide range of formats, key systems, and security levels for commercial projects worldwide. Whether you need standard cylinders, restricted key systems, or electronic ready cores, EOS SECURE provides reliable performance, consistent quality, and dependable technical support. Secure your business with solutions built for long term stability, contact us today.