Table of Contents

ToggleWhat a Lever Handle Lock Is and Why It’s Widely Used

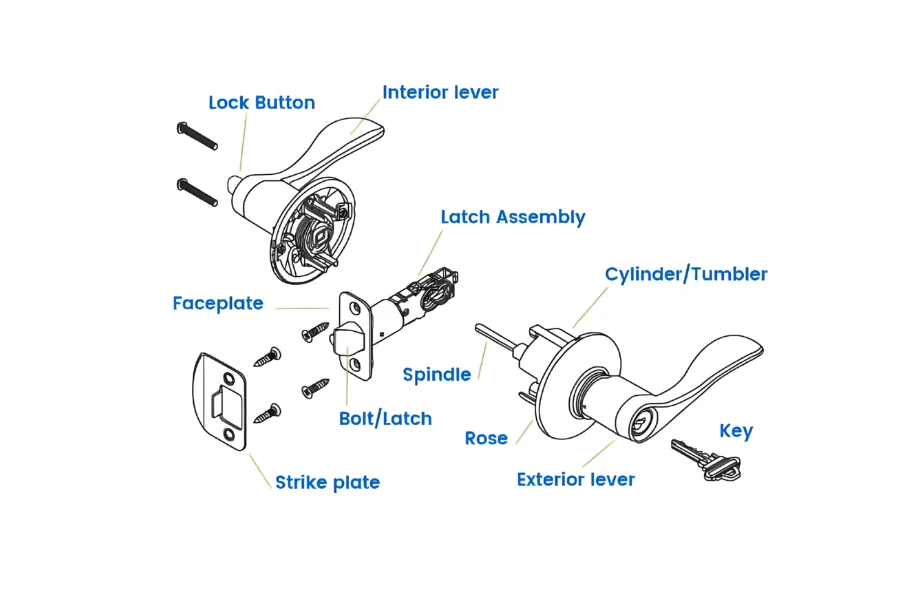

A lever handle lock is a door locking mechanism operated by pushing down or lifting a lever handle. This motion retracts the latch inside the lock body, allowing the door to open or close smoothly.

Because lever handles require less grip strength and wrist rotation, they follow ergonomic design principles and are widely used in residential, commercial, and public buildings. They are especially suitable for accessibility-focused environments.

Compared with traditional knob locks, lever handle locks are easier to grasp and operate. This makes them a practical option for users of all ages, including people with limited hand strength or mobility challenges. For small businesses with frequent staff movement, lever handle locks reduce daily friction at entry points and support consistent, reliable access across shifts.

Common Types of Lever Handle Locks and Where They’re Used

Lever handle locks are available in several configurations, each designed for specific functional and security needs.

Privacy lever locks

These locks include an internal locking mechanism, often with a privacy button or emergency release. They are commonly used in bedrooms and bathrooms where temporary privacy is required.

Passage lever locks

Passage levers do not include a locking function. They control the latch only and are suitable for hallways, closets, and storage rooms where access restriction is not needed.

Dummy lever locks

Dummy levers are non-functional handles used purely for appearance. They are typically installed on double doors or decorative panels that do not require latching.

Keyed lever locks

Keyed lever locks combine lever operation with key-based locking. They provide higher security and are commonly used on exterior doors, offices, and restricted areas.

Mortise lever locks

Mortise lever locks use an embedded lock body and cylinder structure, offering improved resistance to forced entry. They are often selected for commercial entrances and high-traffic doors.

Cylindrical lever locks

Cylindrical lever locks use a unified cylinder mechanism that moves as a single unit. They provide smooth operation and are widely used in public buildings and accessibility-focused doors.

EOS SECURE note

EOS SECURE supplies a wide range of high-security lock cylinders, including European profile cylinders and master key system cylinders. These solutions are designed to integrate with lever handle hardware, supporting different security levels for residential and commercial applications.

Lever Handle Locks vs. Knob Locks – Which One Fits Your Door and Use Case

When selecting between lever handle locks and knob locks, several practical factors should be considered.

Operation

Lever handle locks require minimal force and support accessibility standards. Knob locks require firm grip and rotation, which may be challenging for some users.

Security

Lever handle locks typically use more complex internal structures and offer better resistance to forced entry. Knob locks are generally more vulnerable to picking and impact attacks.

Compliance

Lever handle locks are commonly used in ADA-compliant environments. Knob locks are more typical in standard residential applications.

Installation

Lever handle locks require attention to orientation and handle direction during installation. Knob locks are simpler and more universally interchangeable.

Design

Lever handle locks are available in modern and commercial-friendly styles. Knob locks follow more traditional design conventions.

Cost

Lever handle locks usually fall into a mid-to-high price range, especially when paired with high-security cylinders. Knob locks are typically more cost-effective.

Installing and Maintaining a Lever Handle Lock – What to Expect

Installation Steps

- Remove the existing lock and clean the door surface.

- Mark drilling points using the new lock template.

- Drill holes and install the lock body and cylinder.

- Attach the lever handles and adjust orientation.

- Test latch movement and locking performance.

Maintenance Recommendations

- Clean the handle surface regularly and avoid corrosive cleaners.

- Lubricate the cylinder and moving components every six months.

- Check mounting screws and handle stability.

- Inspect latch alignment if resistance or jamming occurs.

EOS SECURE service support

EOS SECURE provides customized lock solutions through OEM and ODM services. Based on door type, material, and security requirements, we help configure compatible lever handle lock systems and offer installation guidance and after-sales support.

How Secure Are Lever Handle Locks in Real-World Use

Advantages

- Stronger resistance to forced entry compared with standard knob locks.

- Availability of models certified to standards such as EN1303 and SKG.

- Compatibility with smart lock cylinders allows businesses to upgrade from mechanical keys to managed credentials without replacing existing door hardware.

Limitations

- Not suitable for extremely thick or specialized door materials.

- Installation requires drilling, which may affect door structure.

- Entry-level models may still be vulnerable to professional tools.

EOS SECURE security solutions

EOS SECURE high-security cylinders and smart lock systems use patented mechanical structures and encrypted designs. Features include resistance to drilling, picking, and impact attacks, making them suitable for commercial buildings and rental properties with higher security demands.

What’s Next for Lever Handle Locks and How to Plan Ahead

Lever handle locks continue to evolve alongside access control systems.

- Smart integration is increasing, linking mechanical locks with digital credentials.

- Accessibility-focused design is becoming standard as populations age.

- High-security cylinders and anti-destruction features are gaining priority.

EOS SECURE outlook

EOS SECURE continues to develop lock cylinders and mechanical lock systems that meet international standards. Our focus is delivering secure, practical, and scalable locking solutions for residential, commercial, and rental environments.

EOS SECURE – Lock Solutions Built for Long-Term Security

EOS SECURE delivers precision-engineered mechanical and electronic lock cylinders backed by more than a decade of manufacturing expertise. Established in 2011, our ISO9001 and ISO14001 certified factory produces lock cylinders compliant with international standards such as EN1303 and SKG. With advanced CNC manufacturing and strict quality control, EOS SECURE supports both small-batch customization and large-scale production. Explore EOS SECURE solutions to strengthen your business security with long-term stability.

FAQ

Are lever handle locks suitable for exterior doors

Yes. Lever handle locks can be used on exterior doors when paired with a keyed mechanism and a high-security cylinder. For business or rental properties, it’s important to select models with certified resistance features and consider additional protections such as door reinforcement or access monitoring for higher-risk entry points.

Can lever handle locks integrate with smart systems

Yes. Many lever handle locks support smart cylinder upgrades, allowing businesses to move from mechanical keys to digital credentials. This enables features such as fingerprint access, PIN codes, and app-based remote management without replacing existing door hardware, supporting gradual security upgrades as operational needs grow.

Is installation complicated

Installation is generally straightforward for standard doors. However, proper alignment of the latch, cylinder, and handle orientation is critical for long-term reliability. For commercial environments or high-use doors, professional installation is recommended to ensure consistent operation and to avoid premature wear caused by misalignment.

How can the security level of a lever handle lock be evaluated

Security level can be assessed by reviewing recognized certifications such as ANSI or EN1303, examining cylinder anti-pick and anti-drill features, and confirming whether the lock supports master key or access control systems. These factors provide a clearer indication of real-world protection than appearance or handle design alone.

Can lever handle locks be rekeyed

Yes. Most lever handle locks allow rekeying or cylinder replacement without changing the entire lock set. This is especially useful for businesses managing staff turnover or access changes. Rekeying should be performed by a qualified locksmith or supplier to maintain security integrity and system compatibility.

How to lock a lever door handle

Locking a lever handle depends on the lock type. Privacy levers use an internal button or turn mechanism, while keyed levers require a key to secure the door. In commercial settings, locking behavior is often determined by the cylinder system rather than the handle itself, emphasizing proper configuration during selection.