Euro cylinder locks stand as one of the most prevalent security solutions across residential and commercial properties throughout Europe and beyond. These versatile locking mechanisms offer a blend of convenience, adaptability, and robust protection that has made them the go-to choice for everything from front doors to internal office spaces. Understanding the intricacies of these locks—from their basic operation to their advanced security features—is fundamental for anyone looking to enhance their property’s security. Whether you’re a homeowner seeking to upgrade your front door or a facilities manager responsible for an entire building, making an informed choice about your euro cylinder lock can mean the difference between adequate protection and exceptional security. This comprehensive guide will walk you through everything you need to know about these essential security components, empowering you to make the best decision for your specific needs.

Table of Contents

ToggleWhat is a Euro Cylinder Lock?

The euro cylinder lock, often referred to as a barrel lock cylinder or euro lock cylinder, has a rich history dating back to the original pin tumbler patent in 1805. Today, it represents one of the most popular locking systems among locksmiths and architectural ironmongers alike. The term “euro” refers specifically to the standardized profile of the lock—its distinctive oval shape that fits into a corresponding slot in the door. This profile has become the benchmark for countless residential and commercial applications throughout Europe and is increasingly adopted worldwide.

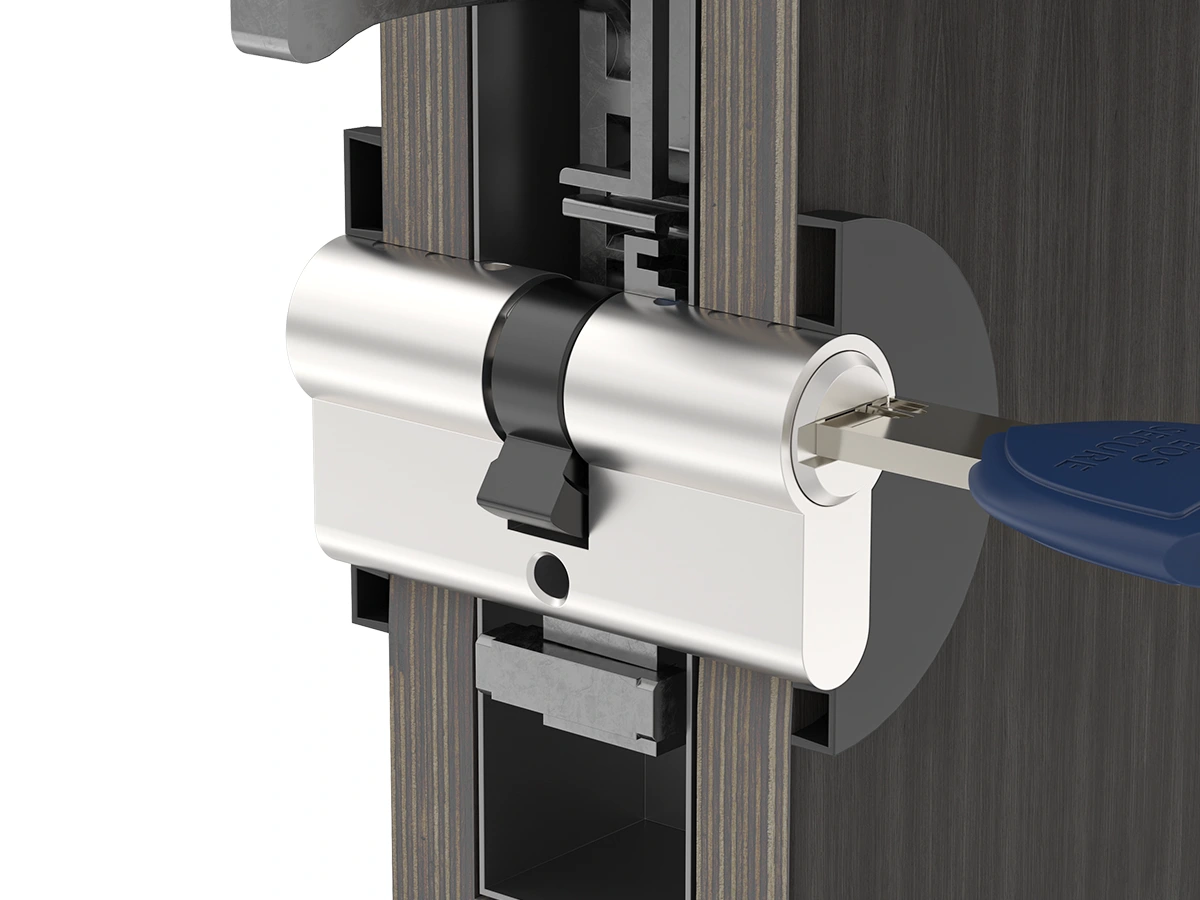

Structurally, a euro cylinder lock consists of a cylindrical barrel housing a sophisticated pin tumbler mechanism. When you insert the correct key, the varying cuts along its blade align the pins inside the lock to a specific height, allowing the cylinder to rotate and operate the locking mechanism. This elegant yet effective design provides reliable security while maintaining straightforward operation. One of the most significant advantages of euro profile cylinders is their ease of replacement; unlike traditional mortise locks that require extensive door modification, replacing a euro cylinder lock typically involves removing a single screw, sliding out the old cylinder, and inserting a new one—a process that often takes less than five minutes.

The working mechanism of these locks centers on their pin tumbler system. Standard euro cylinder locks typically feature either five or six pins, though high-security models may contain up to eleven. These pins are divided into upper and lower sections, with springs applying constant pressure to keep them in place. When no key is inserted, the pins obstruct the rotation of the plug. The correct key has precisely spaced ridges that push each pin to exactly the right height so that the gap between the upper and lower pins aligns perfectly with the shear line, allowing the plug to turn freely. This sophisticated yet reliable mechanism has stood the test of time, proving itself as the foundation of modern physical security for countless applications.

How do Euro Cylinder Locks Work?

Understanding the internal mechanism of euro cylinder locks provides valuable insight into both their reliability and their security vulnerabilities. At the heart of every euro lock cylinder lies a precision-engineered pin tumbler system that has been refined over two centuries of development. This system represents a masterpiece of mechanical engineering—simple in concept yet sophisticated in execution.

The basic mechanism consists of a series of pin pairs—upper pins (drivers) and lower pins (key pins)—arranged in a line within the cylinder. Springs above the upper pins keep constant pressure on the entire stack, preventing the plug (the central part that turns when the correct key is inserted) from rotating freely. Each lower pin is cut to a specific length corresponding to the depth of the cuts on the authorized key. When you insert the correct key, its unique biting pattern lifts each pin pair to exactly the right height so that the meeting point between the upper and lower pins aligns perfectly with the shear line—the gap between the plug and the outer housing. This alignment allows the plug to rotate freely, activating the cam that extends or retracts the deadbolt.

Thumb-Turn Cylinder variants operate on a slightly different principle. While they maintain the same pin tumbler mechanism on the external keyed side, the internal component replaces the keyway with a simple thumb-operated lever. This design allows for quick, keyless exit from the inside—an essential safety feature in emergency situations where every second counts. The thumb-turn mechanism directly engages with the same plug system, ensuring that the security provided is identical whether operating the lock from inside or outside.

The distinction between 5 Pin Cylinder Locks and 6 Pin Cylinder Locks represents a significant security consideration. Five-pin cylinders, while cost-effective and suitable for internal applications, offer fewer possible key combinations and are generally considered entry-level security. In contrast, six-pin cylinders provide exponentially more possible key combinations, making them substantially more resistant to picking attempts and brute force attacks. This additional security margin makes six-pin cylinders the recommended choice for all external doors where security is a priority. The internal configuration of these pins can be further enhanced with security features such as spool pins or serrated pins that actively resist manipulation attempts, providing additional layers of protection against sophisticated attack methods.

Security Features of Euro Cylinder Locks

As euro cylinder locks have evolved, manufacturers have developed countermeasures against common methods of attack. Understanding these security features enables informed decision-making when selecting locks for different applications, particularly for external doors where security requirements are highest.

Anti-Snap Euro Cylinders

Anti-snap euro cylinders address one of the most prevalent physical attacks on traditional euro lock cylinders: lock snapping. This method exploits the inherent weakness of cylinders that protrude from the door, allowing attackers to apply sufficient leverage to break the cylinder at its weakest point. Anti-snap cylinders incorporate a carefully engineered “sacrificial” section designed to break away under extreme force while protecting the vital internal mechanism. This controlled failure means that even if an attacker successfully snaps the external portion of the cylinder, the locking mechanism remains engaged and operational, preventing entry. For any external door, particularly those in areas with higher burglary rates, anti-snap euro cylinders represent a fundamental security requirement rather than an optional extra.

Anti-Drill Euro Cylinders

Anti-drill euro cylinders incorporate hardened steel plates or pins at critical points within the lock mechanism to resist drilling attacks. Standard cylinders can be vulnerable to attackers using power drills to destroy the pin tumblers or the core mechanism, allowing easy manipulation of the lock. Anti-drill versions feature specially treated steel components that blunt or break drill bits, significantly increasing the time and effort required to compromise the lock through this method. This additional resistance often proves sufficient deterrent, as burglars typically seek quick, quiet entry methods rather than noisy, time-consuming attacks that draw attention. When selecting euro profile cylinders for high-security applications, verified anti-drill protection should be a key consideration.

Anti-Bump Euro Cylinders

Anti-bump euro cylinders are specifically engineered to resist lock bumping, a technique that uses specially modified keys to transfer kinetic energy to the pin tumblers, momentarily creating perfect alignment and allowing the lock to be opened. This method has become increasingly concerning as it requires minimal skill yet can compromise many standard cylinders in seconds with little noise or visible damage. Anti-bump cylinders incorporate various countermeasures such as modified pin designs, magnetic components, or side pins that prevent the transfer of kinetic energy or require additional manipulations beyond simple bumping. For properties where discrete, non-destructive entry attempts are a concern, anti-bump euro cylinders provide essential protection against this sophisticated attack method.

Anti-Pick Euro Cylinders

Anti-pick euro cylinders feature specialized pin configurations and other design elements that dramatically increase the difficulty of manipulating the lock using picks and tension wrenches. Traditional pin tumbler locks can be vulnerable to skilled manipulation where the attacker carefully sets each pin to the shear line without the correct key. Anti-pick versions may incorporate spool pins, serrated pins, or mushroom pins that provide false feedback or bind at unexpected points during picking attempts, frustrating even experienced lock pickers. Additionally, some high-security euro cylinder locks feature side bars, magnetic elements, or rotating pins that require simultaneous manipulation in multiple dimensions, making conventional picking techniques virtually impossible. For commercial applications or high-value residential properties, these advanced features provide crucial protection against covert entry attempts.

Types of Euro Cylinder Locks

The diverse security requirements of different properties and applications have led to the development of several distinct types of euro cylinder locks. Understanding these variations is crucial when selecting the most appropriate lock for your specific needs. Each type offers unique advantages tailored to particular use cases, from high-security main entries to convenient internal access control.

Half Euro Cylinder

Half euro cylinders, sometimes called single euro lock cylinders, feature a keyway on only one side of the lock, with the opposite side typically consisting of a simple blank plate or direct connection to the internal mechanism. This configuration makes them ideal for applications where keyed access is only required from one side, such as garage doors, storage cabinets, or internal utility rooms. Their simplified design often makes them more cost-effective than double-sided variants while still providing adequate security for these secondary applications.

However, their limited functionality makes them unsuitable for main entry doors where access might be needed from both sides.

Double Euro Cylinder

Double euro cylinders, also known as full euro cylinder locks, feature keyways on both ends of the lock, allowing operation from either side of the door. This symmetrical design provides enhanced security for external doors, as intruders cannot simply break adjacent glass and reach inside to unlock the door—they would still need the correct key to operate the internal cylinder. This characteristic makes double cylinders the preferred choice for main entry doors, particularly in properties with glass panels near the door handle.

However, it’s important to consider emergency egress requirements, as some building regulations may restrict their use in certain multi-occupancy buildings where quick exit is essential for safety.

Thumb-Turn Euro Cylinder Locks

Thumb-turn euro cylinder locks represent a hybrid design that combines the security of a keyed external mechanism with the convenience of quick internal operation. These locks feature a standard keyway on the external side but replace the internal keyway with a thumb-operated turn knob. This configuration allows occupants to exit quickly without fumbling for keys—an essential safety feature in emergency situations.

Additionally, thumb-turn cylinders are ideal for people with mobility issues or arthritis who may struggle with traditional keys. Many modern thumb-turn designs incorporate safety features that prevent external manipulation through the letterbox or nearby broken glass, maintaining security while offering convenience.

Anti-Snap Euro Cylinder

Anti-snap euro cylinders are specifically engineered to resist one of the most common physical attacks on euro profile cylinders: lock snapping. This brutal attack method exploits a weakness in standard cylinders where excessive force applied to the exposed portion of the cylinder causes it to break at a predetermined point, allowing the attacker to manipulate the internal mechanism.

Anti-snap cylinders incorporate a specially designed sacrificial snap line that controls exactly where the cylinder will break if attacked, leaving the internal mechanism intact and operational. This crucial security feature has become increasingly important for external doors, particularly in areas with higher crime rates, making anti-snap cylinders a recommended minimum standard for all perimeter doors.

Key Types for Euro Cylinder Locks

The security of any euro cylinder lock is intrinsically linked to the key that operates it. Over the years, manufacturers have developed various key types with differing levels of complexity, security features, and resistance to unauthorized duplication. Understanding these differences is essential when selecting a lock that balances convenience with protection against key-based attacks.

Comparison of Euro Cylinder Key Types

| Key Type | Security Level | Duplication Control | Common Applications |

| Yale Key | Medium | Limited | Traditional residential properties |

| Computer Key | Medium-High | Moderate | Modern residential and commercial |

| Normal Key | Basic | Minimal | Low-security internal doors |

| Security Key | High | Restricted | High-security applications |

| Alike Key | Varies | Varies | Multi-door convenience systems |

| General Master Key | High | Professional restricted | Complex commercial systems |

Yale Key

The Yale key represents one of the traditional key profiles for european door locks. Characterized by its classic paracentric design with cuts along both edges, this key type offers reasonable security while maintaining widespread availability for authorized duplication. While modern high-security keys have largely surpassed the Yale design in terms of pick resistance and manipulation protection, these keys still find extensive use in traditional residential properties and older lock systems where complete replacement isn’t practical or necessary.

Computer Key

Computer keys represent an evolution in key technology, featuring precision-milled cuts that require specialized computerized equipment for accurate duplication. Unlike traditional hand-cut keys, computer keys benefit from exacting manufacturing tolerances that ensure consistent operation and enhanced pick resistance. The precise nature of these keys means they typically operate with smoother action and reduced wear on the internal pin tumblers of your euro cylinder lock. While duplication requires access to specialized equipment, this key type offers an excellent balance between security and practical convenience for most residential and commercial applications.

Normal Key

Normal keys, often referred to as standard or basic keys, represent the most economical option for euro cylinder locks. These keys typically feature simple, mechanically-cut biting patterns with minimal security features. While perfectly adequate for low-security applications such as internal office doors or storage cabinets, their simple design and widespread compatibility with basic key-cutting machines make them unsuitable for perimeter security where resistance to unauthorized duplication is a priority. For interior applications where convenience outweighs security concerns, however, normal keys offer a cost-effective solution.

Security Key

Security keys represent the pinnacle of key technology for euro profile cylinders, incorporating advanced features designed specifically to resist picking, bumping, and unauthorized duplication. These keys often feature patented profiles that are legally protected against reproduction without authorization, with registered blanks only available to licensed locksmiths. Additional security elements may include laser-etched side cuts, magnetic components, or dimple configurations that operate sophisticated pinning systems within the cylinder. For high-security applications or properties containing valuable assets, investing in a euro cylinder lock system with security keys provides peace of mind through enhanced physical protection and key control.

Alike Key

Alike key systems offer the convenience of operating multiple euro cylinder locks with a single key. This configuration, known as “keyed alike,” is ideal for properties with multiple external doors or multi-room access systems where carrying numerous separate keys would be impractical. While the security level of each individual lock remains unchanged, the operational convenience can be significant. It’s important to note that keyed alike systems should be implemented thoughtfully, as any lost or compromised key will require replacing all locks in the system to restore security.

General Master Key (GMK)

General Master Key (GMK) systems represent the most sophisticated keying arrangement for euro cylinder locks, allowing both individual specific keys (differ keys) to operate single doors while a master key can operate all locks within the system. This hierarchical approach is invaluable for commercial properties, rental units, or large facilities where different individuals require access to different areas while management maintains overall access control. While more complex to implement and maintain, a well-designed master key system provides unparalleled flexibility for access management without compromising security. These systems require professional design and implementation to ensure that master keying doesn’t introduce security vulnerabilities through cross-keying complications.

Which Types of Doors Are Suitable for Euro Cylinder Locks?

The remarkable versatility of euro cylinder locks lies in their standardized profile, which makes them compatible with an extensive range of door types and materials. This universal compatibility is a primary reason for their widespread adoption across both residential and commercial sectors. Whether you’re securing a traditional home or a modern office building, there’s likely a euro door lock solution that fits your specific needs.

uPVC Door Cylinder Locks

uPVC doors are the most common application for euro cylinder locks. Their modular design features a pre-cut oval slot, making lock replacement straightforward. A proper euro cylinder lock for uPVC should be anti-snap and sized correctly to sit flush with the handle, preventing it from being a target for physical attacks.

Aluminium Door Euro Locks

Modern aluminium doors often use sleek, minimalist profiles that integrate perfectly with euro profile cylinders. The robust nature of aluminium frames provides excellent security, which is enhanced when paired with a high-security cylinder. These european door locks offer a durable and corrosion-resistant solution for contemporary commercial and residential buildings.

Garage Door Euro Cylinder Locks

Securing garages, sheds, and outbuildings is a key use for euro cylinder locks. They provide a higher level of security than simple padlocks. For garage doors, a double euro cylinder is often recommended to prevent intruders from breaking a window and unlocking the door from the inside.

Cylinder Locks for Storage Units

For self-storage facilities or commercial storage units, euro cylinder locks are ideal. They can be configured in master key systems, allowing management with a single key while each tenant has their own unique key. This makes euro lock cylinders a scalable and secure access control solution.

Patio Door Cylinder Locks

Patio doors are a common entry point for burglars. A high-security euro cylinder lock is crucial for these large glass doors. Choosing an anti-snap, anti-drill euro cylinder significantly enhances the physical security of the door, acting as a strong deterrent even if the glass is vulnerable.

French Door Euro Locks

French doors typically use a multi-point locking system operated by a euro cylinder. When you turn the key, the euro lock cylinder engages bolts at the top and bottom of the door, in addition to the main deadbolt, creating a much more secure seal around the entire door perimeter.

Wooden Door Cylinder Locks

Traditional and modern wooden doors are perfectly suited for euro cylinder locks. The lock is discreetly installed within the door, preserving its aesthetic. For wooden doors, it’s essential to use a euro cylinder with a weather-proof finish to protect against moisture and ensure long-term smooth operation.

Steel Door Euro Locks

The immense strength of a steel door demands an equally strong lock. High-security euro cylinder locks with anti-drill, anti-snap, and anti-pick features are the perfect match. They complete the security package, ensuring the cylinder is the weakest point of entry.

Standards and Accreditations for Euro Cylinder Locks

When selecting a euro cylinder lock, understanding the relevant standards and accreditations provides crucial insight into the product’s quality, durability, and security performance. These benchmarks, developed through extensive testing and industry consensus, help consumers distinguish between basic products and those offering genuine, proven protection against various methods of attack.

BS EN 1303

BS EN 1303 represents the primary European standard for cylinder locks, establishing minimum requirements for performance and security across multiple parameters. This comprehensive standard evaluates cylinders through a series of rigorous tests assessing factors such as torque resistance, corrosion resistance, durability under repeated use, and temperature tolerance. Cylinders meeting BS EN 1303 receive an eight-digit classification code that precisely indicates their performance across these different criteria. For specifiers and consumers, this standard provides assurance that the euro profile cylinder has been manufactured to consistent quality standards and will perform reliably under normal operating conditions throughout its expected service life.

TS 007

TS 007 is a British Standard specifically developed to address the particular vulnerabilities of euro cylinder locks to methods like snapping, picking, and drilling. This standard employs a star-rating system where cylinders can achieve 1-star or 3-star ratings based on their resistance to these attack methods. A 3-star cylinder offers substantial resistance on its own, while a 1-star cylinder requires combination with 2-star door hardware (handles or escutcheons) to achieve equivalent protection. The TS 007 accreditation is particularly valuable when selecting european door locks for external applications, as it specifically addresses the real-world attack methods most commonly employed by burglars in many European countries.

Sold Secure

Sold Secure certification, administered by the Master Locksmiths Association in the UK, takes a different approach by testing products against actual attack techniques using tools commonly employed by burglars. This practical testing methodology evaluates not just theoretical strength but real-world performance when subjected to determined attack. The Sold Secure rating system includes Bronze, Silver, Gold, and Diamond levels, with Diamond representing the highest security rating achievable. For consumers seeking the utmost confidence in their euro cylinder lock selection, the Sold Secure certification, particularly at Diamond level, provides assurance that the product has survived intensive attack testing by security professionals using methods reflecting current criminal techniques.

Star Ratings of Euro Cylinder Locks

The star rating system for euro cylinder locks provides a straightforward method for consumers to identify products offering proven resistance to common attack methods. Developed under the TS007 standard, this classification system helps differentiate between basic cylinders and those offering genuine, tested security properties.

1 Star Euro Cylinder Lock products demonstrate resistance to techniques such as drilling, picking, and snapping but must be installed with appropriate 2-star rated door hardware (handles or escutcheons) to achieve a complete 3-star security system. These cylinders typically incorporate anti-snap features and basic drill resistance but rely on reinforced door furniture to provide comprehensive protection against physical attacks targeting the cylinder itself. For most residential applications, a properly installed 1-star cylinder combined with 2-star hardware represents a significant security upgrade over standard cylinders while remaining cost-effective.

3 Star Euro Cylinder Lock products offer the highest level of standalone security within this rating system, providing substantial resistance to snapping, drilling, picking, and bumping without requiring additional protective hardware. These cylinders undergo rigorous testing to verify their performance against sustained attacks using tools and techniques representative of those employed by burglars. The 3-star rating indicates that the euro cylinder lock itself has demonstrated robust protection, making it ideal for situations where replacing complementary door hardware isn’t practical or desirable. For maximum security, particularly in high-risk areas or for properties containing valuable assets, 3-star cylinders represent the current benchmark for standalone cylinder security.

Euro Cylinder Lock Set-Ups

Beyond selecting individual locks, understanding the different configuration options for euro cylinder locks enables the creation of integrated access systems tailored to specific property requirements. These set-ups range from simple convenience configurations to sophisticated hierarchical systems for complex commercial applications.

Keyed Alike systems involve multiple euro cylinder locks configured to operate with the same key. This arrangement offers significant convenience for properties with multiple external doors, as occupants need carry only a single key for all access points. Common applications include homes with front and back doors, small office suites with multiple entry points, or storage facilities with several individual units. While the security of each individual lock remains unchanged, this configuration simplifies key management for authorized users. However, it’s important to recognize that any compromised key in a keyed alike system will require replacing all cylinders to restore security, making careful key control essential.

Keyed Differ represents the standard configuration for individual euro cylinder locks, where each lock has a unique key that operates only that specific cylinder. This approach ensures that access to one door doesn’t grant access to others, providing compartmentalized security ideal for multi-tenant buildings, office environments with sensitive areas, or properties where different individuals require access to different spaces. While key management becomes more complex as the number of locks increases, this configuration limits the security impact of any single lost or compromised key, as only the specific corresponding lock requires replacement.

Master Key Systems create a hierarchical access structure where individual euro profile cylinders can be operated by both unique “change” keys and a universal “master” key that operates all locks in the system. These sophisticated arrangements are invaluable for commercial properties, educational institutions, healthcare facilities, or multi-tenant residential buildings where different individuals require different access levels while management maintains overall access capability. A well-designed master key system balances convenience with security, ensuring that the master keying process doesn’t introduce vulnerabilities through overly complex pinning arrangements. Professional design and implementation are essential for these systems to ensure both operational convenience and maintained security throughout the property.

The Material of the Euro Cylinder Locks

The construction material of a euro cylinder lock significantly influences its durability, corrosion resistance, and overall security performance. Different materials offer varying balances between strength, weather resistance, cost, and longevity, making material selection an important consideration based on the specific application and environmental conditions.

Brass Euro Profile Cylinder

Brass euro profile cylinders represent the premium choice for most applications, offering an exceptional balance of strength, corrosion resistance, and machinability. The inherent lubricity of brass—its natural slippery quality—ensures smooth key operation and reduced wear on both the key and internal components over time. Brass’s excellent corrosion resistance makes it particularly suitable for external doors exposed to rain, humidity, and temperature fluctuations, as it won’t rust or degrade like ferrous metals. Additionally, brass develops a protective patina over time rather than corroding destructively, ensuring long-term reliability. For coastal areas with salt-laden air or regions with high pollution levels, brass euro cylinder locks offer superior performance compared to alternative materials. While typically commanding a higher price point than zinc or aluminum alternatives, brass cylinders provide long-term value through extended service life and consistent performance.

Zinc Alloy Euro Profile Cylinder

Zinc alloy euro profile cylinders offer a cost-effective alternative to brass while maintaining reasonable durability and corrosion resistance. Through die-casting manufacturing processes, zinc alloys can produce complex shapes with good dimensional accuracy, ensuring proper fit and function within the door assembly.

While generally strong enough for most residential applications, zinc alloys may be more susceptible to impact damage or forced entry attempts compared to brass, particularly in lower-quality formulations. Corrosion resistance varies significantly between different zinc alloy grades, with some formulations potentially developing oxidation or surface deterioration when consistently exposed to moisture. For internal applications or external doors in sheltered locations, zinc alloy european door locks represent a budget-conscious choice, though they may not offer the same long-term reliability as their brass counterparts in demanding environmental conditions.

Aluminum Alloy Euro Profile Cylinder

Aluminum alloy euro profile cylinders provide a middle ground between brass and zinc in terms of both cost and performance. Aluminum’s natural corrosion resistance makes it suitable for external applications, particularly in environments where moisture is a concern. However, aluminum’s relative softness compared to brass can make it more susceptible to wear over time, particularly in high-traffic applications where keys are inserted and removed frequently.

Additionally, aluminum may not provide the same level of resistance to drilling or physical attacks as harder materials, though this can be mitigated through additional hardening processes or security inserts at critical points. For applications where budget constraints preclude brass cylinders but better corrosion resistance than zinc is required, aluminum alloy euro lock cylinders offer a viable compromise, though potentially with some sacrifice in long-term durability.

How to Measure a Euro Cylinder Lock

Proper measurement represents perhaps the most critical step when replacing or upgrading a euro cylinder lock. An incorrectly sized cylinder can compromise both security and functionality, creating vulnerabilities that negate even the most advanced security features. The measurement process varies slightly depending on whether you’re working with a double, single, or thumb-turn cylinder, but follows the same fundamental principles.

Euro Cylinder Door Compatibility & Thicknesses

Before measuring your existing euro cylinder lock, it’s helpful to understand the relationship between door thickness and cylinder length. Standard internal doors typically accommodate shorter cylinders, while thicker external doors, particularly uPVC or composite models, require longer specifications. The most common euro cylinder lock sizes range from 60mm to 100mm, with specialty applications sometimes requiring even longer dimensions. uPVC doors often require asymmetric cylinders where the external measurement differs from the internal measurement to accommodate the specific geometry of the door profile and handle mechanism. Understanding your door type provides useful context for the measurements you’ll take, helping identify any potential anomalies before proceeding with purchase and installation.

How to Measure a Double Cylinder

Measuring a double euro cylinder lock requires determining both the external (A) and internal (B) measurements from the center fixing point to each end. Begin by locating the fixing screw in the center of the cylinder—this serves as your reference point for all measurements. Using a tape measure or ruler, measure from the center of the screw to the outer edge of the cylinder on the external side (Measurement A). Repeat this process on the internal side (Measurement B). Finally, measure the overall length to verify that it equals the sum of A and B. This verification step helps ensure accuracy, particularly important when the cylinder cannot be removed before purchasing its replacement. For uPVC doors, pay particular attention to how much the cylinder protrudes from the handle rose on each side—ideally, it should be flush or protrude no more than 3mm to prevent easy gripping for snapping attacks.

How to Measure a Single Cylinder

Single euro lock cylinders, used where key operation is only required from one side, follow a similar measurement process but with only one active measurement. Again, begin by locating the central fixing screw. Measure from the center of this screw to the outer edge of the key-operated side—this represents your critical functional measurement. Then measure from the center screw to the opposite (non-keyed) end. While this second measurement matters for fit, the key-operated side measurement determines functionality. When replacing half cylinders, note any unusual configurations where the fixing point might not be centered, though this remains relatively rare in standard euro profile cylinders.

How to Measure a Thumb Turn Cylinder

Thumb turn euro cylinder measurement follows the same fundamental principle as double cylinders but requires additional consideration of the thumb turn mechanism itself. Measure from the center fixing screw to the outer edge of the key-operated side (external measurement), then from the center screw to the outer edge of the thumb turn mechanism (internal measurement). Note that the thumb turn component typically adds minimal length compared to a standard keyway, but this can vary between manufacturers. When selecting a replacement, ensure the thumb turn mechanism has sufficient clearance to rotate freely without obstructing the door frame or adjacent furnishings when in the unlocked position.

Measure your Euro Cylinder Lock

The specific measurement technique depends on whether your euro cylinder lock remains installed in the door or has been removed:

For an installed cylinder: Insert the key and slightly turn it (approximately 30-45 degrees) to release the locking cam. Measure from the center of the fixing screw to the outer edge of the cylinder on both sides, taking care not to include any protruding key bows in your measurement. Verify by measuring the overall length from edge to edge.

For a removed cylinder: Place the cylinder on a flat surface and measure from each end to the center of the fixing hole, ensuring your measurement includes the cam mechanism in the overall length. Again, verify that the two individual measurements sum to the overall length.

Euro Cylinders can vary in Length

Euro cylinder locks are manufactured in standardized length increments, typically varying by 5mm between common sizes. The most frequent sizes range from 60mm (30mm/30mm) to 100mm (50mm/50mm), with asymmetric variants common for uPVC doors (e.g., 45mm/55mm). When your measurements fall between standard sizes, always round up to the next available size rather than down, as a slightly protruding cylinder can be acceptable while a recessed cylinder creates security vulnerabilities and potential operational issues. Many manufacturers offer specific 100mm euro cylinder lock options for extra-thick doors or specialized applications, though these typically represent the upper end of standard sizing before custom orders become necessary.

How to install a Euro Cylinder Lock

Installing a euro cylinder lock represents one of the most straightforward door hardware replacement tasks, typically requiring minimal tools and expertise. The process generally takes less than ten minutes when following proper procedure, making it an achievable project for most homeowners. Correct installation ensures optimal security and functionality while preventing damage to both the lock and door mechanism.

Begin by removing the existing cylinder. Locate the fixing screw on the door’s edge—typically positioned near the center of the lock mechanism—and loosen it completely. Insert the correct key into the existing cylinder and turn it slightly (approximately 30-45 degrees) to align the cam with the housing, then gently pull the cylinder outward. If resistance occurs, avoid excessive force; instead, gently wiggle the key while maintaining slight outward pressure until the cylinder releases. For thumb-turn models, simply turn the thumb piece slightly while gently pulling the cylinder outward.

With the old cylinder removed, carefully insert the new euro cylinder lock into the vacant housing, ensuring the cam aligns properly with the locking mechanism. The cylinder should slide in smoothly without forcing—if resistance occurs, verify alignment before applying pressure. Once fully seated, insert and tighten the fixing screw until snug, taking care not to overtighten as this can distort the mechanism or strip the screw threads. Test the key operation from both sides, ensuring smooth rotation without binding or excessive resistance. Finally, operate the door handle and deadbolt multiple times to verify proper engagement with the strike plate, making any necessary adjustments to ensure smooth, reliable operation.

Throughout the installation process, handle the new euro profile cylinder with care, avoiding any forceful manipulation that might damage the precision internal components. If at any point the key becomes difficult to turn, remove the cylinder and verify proper alignment before proceeding. Correct installation not only ensures immediate functionality but also contributes to the long-term reliability and security provided by your new euro cylinder lock.

Maintaining a Euro Cylinder Lock

Regular maintenance significantly extends the service life of euro cylinder locks while ensuring consistent, reliable operation. Like any mechanical device, these locks benefit from periodic attention that addresses environmental contaminants, internal wear, and potential operational issues before they compromise security or functionality.

Cleaning and Lubricating your Lock

Proper cleaning begins with removing visible debris from the keyway using compressed air or a small, soft brush. Avoid using metal objects that might damage the precision pins within the mechanism. For exterior euro lock cylinders exposed to environmental contaminants, more thorough cleaning may be necessary using specialized security product cleaners that dissolve accumulated grime without leaving residue. Following cleaning, appropriate lubrication ensures smooth operation while protecting against wear. The lubrication interval depends on usage frequency and environmental conditions, but most european door locks benefit from lubrication every six to twelve months under normal conditions, with more frequent attention in high-use or harsh environments.

Wondering how to Lubricate a Lock?

The lubrication process for euro cylinder locks requires appropriate products and technique to avoid inadvertently causing more harm than good. Insert the lubricant’s extension tube fully into the keyway and apply a brief, moderate spray directly into the mechanism. Immediately insert the key and work it in and out several times to distribute the lubricant evenly throughout the pin chambers. Turn the key fully in both directions to ensure complete coverage of the internal mechanism. Wipe away any excess lubricant from the cylinder face and key to prevent attracting additional dust and debris. Proper lubrication should result in noticeably smoother key operation without any gritty sensation or binding throughout the rotation.

How often should you Clean or Lubricate your Euro Cylinder Lock?

The optimal maintenance frequency for euro cylinder locks depends on several factors including usage patterns, environmental conditions, and the lock’s specific design. High-traffic commercial applications may require quarterly attention, while residential front doors typically benefit from semi-annual maintenance. Coastal properties with salt air exposure or urban environments with higher pollution levels may necessitate more frequent cleaning to prevent corrosive buildup. Indicators that your euro profile cylinder requires attention include keys becoming difficult to insert or remove, rotational stiffness when turning the key, or any gritty sensation during operation. Addressing these symptoms promptly prevents accelerated wear and potential lock failure, ensuring consistent security and convenience.

How to Choose the Best Euro Cylinder Lock?

Selecting the optimal euro cylinder lock requires balancing multiple considerations including security requirements, door type, environmental conditions, and budget constraints. A methodical approach ensures appropriate selection without over-specifying or compromising on essential protection.

Begin by assessing your security needs based on the door’s location and the potential risks. External doors, particularly those with limited oversight or in higher-crime areas, justify investment in high-security cylinders with anti-snap, anti-drill, and anti-pick features, preferably with 3-star TS007 ratings or Sold Secure Diamond certification. Internal doors between secure areas may require less sophisticated protection but should still provide adequate resistance against casual compromise. Consider the value of assets being protected alongside potential insurance implications, as many providers offer premium discounts for properties with certified security hardware.

Next, evaluate compatibility with your specific door type and measurement requirements. uPVC doors often require asymmetric euro cylinder locks to accommodate their specific handle geometry, while wooden doors may need longer cylinders to span thicker profiles. Accurate measurement remains essential, as an improperly sized cylinder creates security vulnerabilities regardless of its technical features. Consider material selection based on your environment—brass for coastal or high-humidity applications, with zinc or aluminum alloys suitable for more protected locations where budget constraints might preclude brass alternatives.

Finally, consider key management requirements and future flexibility. Keyed-alike systems offer convenience for multiple access points while master key systems provide hierarchical access control for complex properties. Patented keyways with restricted duplication capabilities offer additional security against unauthorized key copying, particularly important in multi-tenant environments. Balance these convenience features against potential security implications, as sophisticated keying systems typically command premium pricing but offer long-term benefits through enhanced control and reduced vulnerability to key-based compromises.

Conclusion

Euro cylinder locks represent far more than simple mechanical fasteners—they are sophisticated security devices that form the first line of defense for countless properties worldwide. From their standardized profile that enables easy replacement to their increasingly sophisticated security features that resist evolving criminal techniques, these locks have proven their value through decades of reliable service. Understanding their operation, variations, and proper selection criteria empowers property owners to make informed decisions that appropriately balance security, convenience, and cost.

The journey to proper euro cylinder lock selection begins with accurate measurement and continues through careful consideration of security requirements, environmental conditions, and operational needs. Whether opting for a simple 5-pin cylinder for an internal office or a high-security 3-star anti-snap model for a perimeter door, the principles of proper installation and maintenance remain consistent. Regular care ensures long-term reliability while preserving the security features that justified the original investment.As security technology continues evolving, euro profile cylinders will undoubtedly incorporate even more sophisticated protections against emerging threats. Nevertheless, the fundamental principles of proper selection, installation, and maintenance will remain constant, providing property owners with the knowledge necessary to navigate these advancements while maintaining effective security postures. By applying the comprehensive information contained in this guide, you can confidently select, install, and maintain euro cylinder locks that provide appropriate protection for your specific application, ensuring peace of mind through reliable security. Contact EOS to start your Euro lock cylinder projects.