Cylinder locks remain one of the most reliable ways for small businesses to secure doors, manage keys, and maintain daily operations. They offer a practical balance of strength, convenience, and long term value. This guide explains how they work, why they matter, and how to choose a cylinder lock that supports your business security strategy.

Table of Contents

ToggleUnderstanding Cylinder Locks

What a Cylinder Lock Is

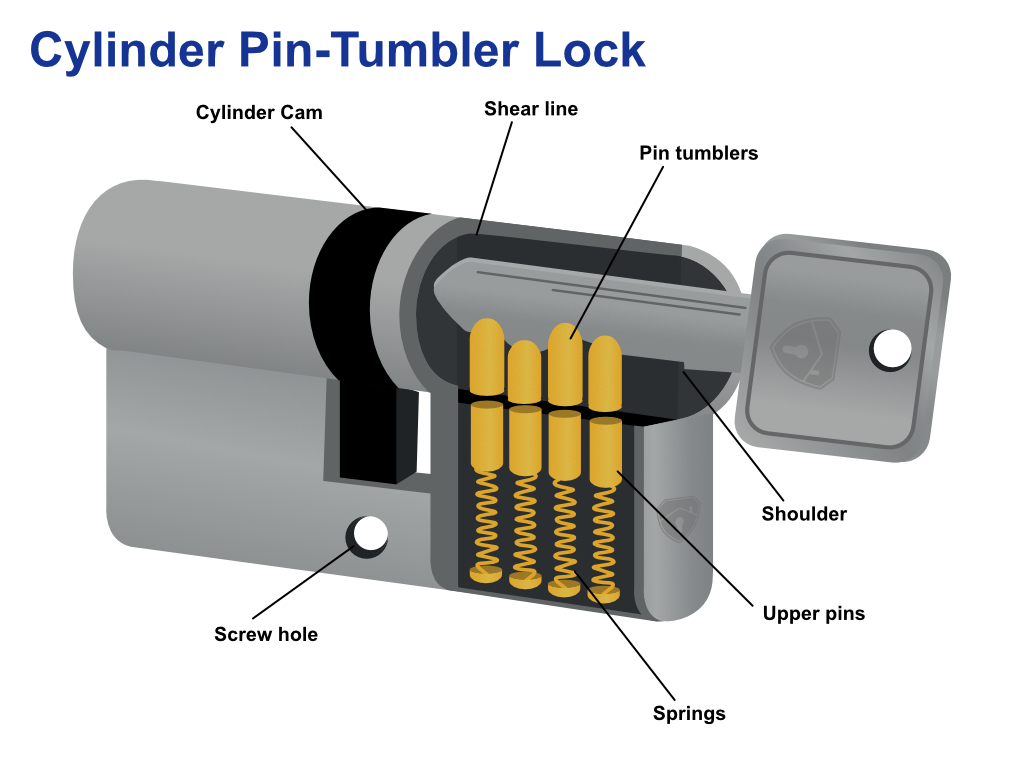

A cylinder lock uses a rotating plug with internal pins that align with a matching key. When the key lifts the pins to the correct height, the plug turns and the door unlocks. This design creates a controlled access point that is simple to manage and easy to maintain.

A standard cylinder includes four key components

- Cylinder plug which holds the internal pins

- Pins which block or release the plug

- Key which sets each pin to the correct height

- Housing which secures the cylinder inside the lock body

This structure gives businesses a dependable mechanical system without complex hardware.

How a Cylinder Lock Works

Cylinder locks operate through a clear mechanical sequence.

- Insert the key which lifts the pin stacks

- The cuts on the key raise each pin to its required height

- When aligned the pins create a clean shear line

- The plug rotates and engages the locking mechanism

Only the correct key can complete this process which helps prevent unauthorized entry.

Common Cylinder Types for Commercial Doors

Businesses use different cylinder profiles depending on door construction, hardware style, and required security level.

Euro Cylinder

Euro cylinders are common in offices, shops, and commercial buildings that use multipoint or mortise systems. They are easy to replace and offer many high security options. Lower grade models may be easier to compromise, so certified versions are recommended.

Rim Cylinder

Rim cylinders work with surface mounted night latches often found on interior service doors or secondary access points. They install quickly and cost less yet basic models provide limited protection.

Oval Cylinder

Oval cylinders are used in commercial mortise cases. They deliver strong durability and weather resistance which suits storefronts and exterior entries. They may cost more and have fewer replacement options.

Functional Formats

Businesses can choose from several operation formats.

- Single cylinder with a key outside and a thumbturn inside

- Double cylinder requiring a key on both sides for controlled access

- Thumbturn cylinder which allows fast exit with an interior turn

- Key and knob combinations for mixed convenience and control

These formats help align access requirements with safety guidelines.

Specialized Options

Some situations require specialized cylinders.

- Construction key models for temporary contractor access

- High security cylinders with reinforced components

- Half cylinders for spaces that only need one sided access

These support a broader range of commercial and property management needs.

Why Cylinder Locks Matter for Business Security

Security Features That Strengthen Commercial Doors

Modern cylinder locks include protective features that help delay or prevent forced entry.

- Anti pick components

- Reinforced cores

- Anti drill inserts

- Anti snap zones

- Restricted key duplication

These features help protect storefronts, offices, and storage areas against common break in methods.

Operational Convenience

Cylinder locks give businesses predictable access control without complicated maintenance.

- Replace the cylinder without removing the entire lock body

- Rekey quickly when staff changes or keys go missing

- Support master key setups for multi door sites

- Integrate with electronic or smart entry upgrades

This helps reduce downtime and limits disruptions to daily operations.

Durability for Long Term Use

Most commercial grade cylinders use brass or stainless steel components. They withstand heavy use, support exterior installations, and perform reliably through seasonal changes. This reduces long term hardware costs for small businesses.

How Cylinder Locks Strengthen Business Security

Protection Against Forced Entry

High security cylinders increase the time and effort required to bypass a door. Reinforced cores and snap resistant zones help maintain protection even if the lock experiences physical force.

Flexible Key Management

Cylinder systems support practical key control.

- Update access after staffing changes

- Rekey or replace cylinders when keys are lost

- Combine with deadbolts or multipoint systems for added layers

Businesses gain the flexibility to adjust access without replacing entire locksets.

Reliable Value Over Time

Certified cylinders deliver consistent performance and durability which supports insurance requirements and strengthens overall building security. This offers long term value for property managers and business owners.

How To Choose the Right Cylinder Lock

Match Security Level to the Door

Start by evaluating the purpose and risk level of each door.

- Street facing entries usually require higher security

- Interior office doors may need simpler control

- Storage and delivery areas may need reinforced models

A door’s location and use help determine the right cylinder strength.

Check Security Certifications

Certifications offer clear performance indicators.

- ANSI and BHMA grades

- BS EN 1303 ratings

- Insurance approved standards

These ratings help assess durability and resistance under real world conditions.

Select Features That Support Your Business

Key decisions include

- The correct cylinder length for the door

- Features such as anti drill or anti snap

- Ease of use for staff members

- Compatibility with future smart entry upgrades

A well chosen cylinder should fit both the hardware and the ongoing demands of your business.

Why Professional Installation Matters

Even strong hardware underperforms when installed incorrectly. A trained locksmith ensures proper alignment and secure placement which protects long term reliability and maintains manufacturer warranties.

Maintaining and Upgrading Cylinder Locks

Routine Maintenance

Regular care helps keep cylinders operating smoothly.

- Lubricate with lock safe products

- Check for stiffness or unusual resistance

- Keep the keyway free of debris

Simple steps extend the life of the hardware.

When To Upgrade

Consider replacing or upgrading a cylinder when

- Staff turnover increases

- A key is lost

- The lock becomes difficult to operate

- Local security conditions change

- The hardware no longer meets current protection standards

A timely upgrade helps maintain consistent security.

What To Look For in an Upgrade

Choose a cylinder with

- Higher security ratings

- Stronger metal components

- Enhanced resistance to drilling or snapping

- Compatibility with your existing lock hardware

A locksmith can help identify options that support your security goals.

Frequently Asked Questions

What is a cylinder lock

A cylinder lock uses a rotating plug with internal pins that align with a matching key. When the pins reach the correct height the plug turns and the door unlocks. It is one of the most common systems used in commercial properties.

How is a cylinder lock different from other locks

The cylinder can be replaced or rekeyed without removing the entire lockset. This allows quick security updates when staff changes or when key control needs to be reset.

Which doors can use cylinder locks

Cylinder locks work with many commercial doors including aluminum, steel, wood, and composite designs. The correct cylinder depends on the door thickness, hardware type, and required security level.

Are cylinder locks secure for businesses

Yes. Modern cylinders include anti pick anti drill anti bump and anti snap protections that help resist common forced entry techniques.

What does anti snap protection do

Anti snap protection reinforces the cylinder so the exposed end does not break easily. If someone tries to snap the lock the protected section helps maintain door security.

How can I confirm that a cylinder is secure

Check for certifications such as ANSI or BS EN 1303. Look for features that improve drill bump and snap resistance. You can also confirm whether the lock meets insurance requirements.

How do I measure a cylinder size

Measure from the center of the fixing screw to each end of the cylinder. The two measurements may differ. A locksmith can verify the numbers to ensure a proper fit.

Is a single cylinder or double cylinder better

Single cylinders allow quick exit with an interior thumbturn. Double cylinders require a key on both sides which supports tighter key control. Choose based on the door’s location and safety requirements.

Can I install a cylinder lock myself

Some users can install basic models yet professional installation ensures correct alignment and full performance. A locksmith confirms that the hardware fits the door and meets safety standards.

Do cylinder locks need regular maintenance

Yes. Light lubrication and periodic checks for stiffness help keep the mechanism working smoothly. Regular care reduces long term issues.

When should a cylinder be replaced

Replace the cylinder if the key becomes difficult to turn if you lose a key or when staffing changes. Upgrading is also helpful when security expectations increase.

Do I need to change the entire lock if I lose a key

Not usually. Most cylinders can be replaced or rekeyed which restores security without removing the entire lockset.

Do cylinder locks work with smart systems

Many commercial cylinders integrate with keypad modules Bluetooth readers and electronic access components. They provide keyless entry while keeping the mechanical cylinder as a dependable backup.

What is a master key system

A master key system allows one key to open multiple locks while each lock keeps its own individual key. This is useful for offices retail spaces and properties with shared access needs.

Will upgrading the cylinder affect my door warranty

Some door manufacturers specify which hardware is approved. Check their guidelines or speak with a locksmith to maintain compliance.

EOS SECURE Closing Statement

EOS SECURE delivers precision engineered mechanical and electronic lock cylinders backed by more than a decade of manufacturing expertise. Established in 2011, our factory operates under ISO9001 and ISO14001 certifications which support consistent quality and environmental management. Every cylinder is produced to meet international standards including EN1303 and SKG. With advanced Swiss type CNC machining centers and scalable production capacity, we support both custom requirements and high volume orders. EOS SECURE provides durable performance, reliable quality, and dependable technical support. Strengthen your building security with solutions designed for long term stability, contact us to explore your options.