Ensuring the safety and proper function of your door lock system begins with selecting and measuring the correct cylinder length. As a manufacturer of precision lock cylinders, we understand that accurate measurements are the first step in ensuring that locks perform as designed. This guide will integrate professional measurement methods, safety tips, and practical advice for choosing the right cylinder length.

Table of Contents

ToggleWhat is Cylinder Length and Why Does It Matter?

Understanding Cylinder Length

Cylinder length refers to the overall length of the lock cylinder, typically measured in millimeters (mm). This length is divided into two parts by the midpoint, which acts as the reference point for measurements.

The Importance of the Midpoint

The midpoint is the key reference point, typically aligned with the center of the fixed screw or edge of the door during installation. It helps measure the left and right sides of the cylinder accurately.

Symmetrical vs. Asymmetrical Cylinders

- Symmetrical Cylinders: Both sides of the midpoint have the same length (e.g., 40-40 for a total of 80mm).

- Asymmetrical Cylinders: The two sides have different lengths (e.g., 45-35 for a total of 80mm). The choice depends on door thickness and handle positioning.

Pro Tip: High-precision cylinders ensure perfect alignment and smooth operation, meeting international standards like EN1303.

Why Accurate Measurement Is Crucial for Security and Function

The Risks of Incorrect Cylinder Length

- Overlong Cylinders: If the cylinder protrudes more than 5mm, it’s easier for tools to grip and snap the cylinder, creating a significant security risk.

- Too Short Cylinders: If the cylinder is too short, it may recess inside the handle, preventing the key from being inserted or turned. This also allows moisture and dust to accumulate, accelerating internal wear and tear.

Getting the Right Fit for Your Door

The correct cylinder length ensures that the locking cam aligns precisely with the locking mechanism, allowing smooth locking and unlocking operations. Even the highest security features will fail if the cylinder is incorrectly sized.

How to Measure Your Cylinder — Two Simple Methods

Tools You Need

- A suitable screwdriver

- A precise ruler or tape measure

Method A: Measuring an Existing Cylinder (Most Accurate)

Step 1: Remove the Cylinder

- Unscrew the center bolt that secures the cylinder.

- Insert the key and rotate it about 30-45 degrees to align the cam, then pull the cylinder out smoothly.

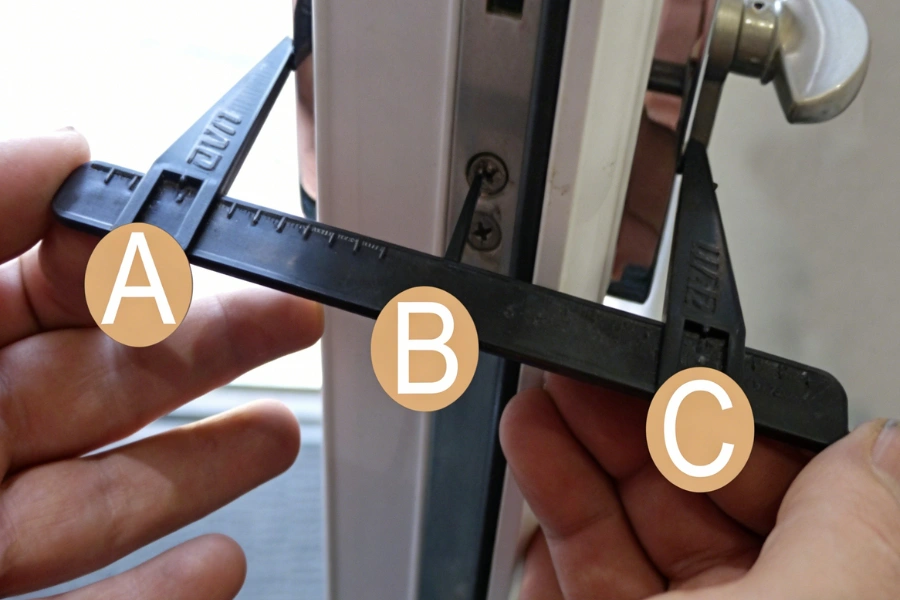

Step 2: Measure the Cylinder

- Place the cylinder flat and align your ruler with the side.

- Find the midpoint, usually indicated by a vertical line or the center of the screw hole.

- Measure A (external length) from the midpoint to one end and B (internal length) from the midpoint to the opposite end.

- Verify the total length by ensuring C = A + B.

Method B: Measuring Without Removing the Cylinder (For New Doors)

Step 1: Identify the Reference Points

- Identify the door’s outer and inner edges, including all furniture and handle fittings.

Step 2: Measure the External Size (A)

- Measure from the outside edge of the door (including fittings) to the center of the screw hole.

Step 3: Measure the Internal Size (B)

- Measure from the inside edge of the door to the same screw hole center.

Step 4: Confirm the Total Thickness (C)

- Measure the door’s overall thickness. C should be equal to A + B, which ensures measurement accuracy.

Choosing the Right Cylinder Length

When to Use a Symmetrical Cylinder

If A = B, you should select a symmetrical cylinder (e.g., 40-40).

When to Use an Asymmetrical Cylinder

If A ≠ B, an asymmetrical cylinder (e.g., 45-35) is required.

Final Validation

- After installation, the cylinder should protrude no more than 3-5mm from the outer handle and should align smoothly with the handle surface.

- On the inner side, the cylinder should not be recessed excessively.

- Ensure the key and thumbturn can rotate smoothly without any sticking

Conclusion

Ensuring the correct cylinder length is essential for both functionality and security. At EOS SECURE, we specialize in precision-engineered lock cylinders that meet rigorous international standards like EN1303 and SKG. With over a decade of manufacturing expertise, our products offer reliable performance, exceptional quality, and tailored solutions for businesses of all sizes. Whether you’re looking for small-batch customization or large-scale production, EOS SECURE provides dependable security solutions designed for long-term stability. Explore our products today to safeguard your business.

FAQ

How do I find the midpoint?

Look for the central screw hole or a marking on the cylinder. On the door, it typically aligns with the center line of the lock panel.

Is a few millimeters difference in A and B significant?

Yes, even a small difference can require an asymmetrical cylinder. Using the wrong size can lead to operational issues or security risks.

What is an "anti-snap cylinder" and how does length affect it?

Anti-snap cylinders feature a weak point that breaks under force, keeping the locking mechanism intact. A cylinder that’s too long and exposed is more vulnerable to snapping, making accurate length crucial for security.

Can euro cylinders be reversed?

Yes, double-ended euro cylinders are symmetrical. For example, a 50/60 cylinder is the same as a 60/50, as long as the total length and A/B dimensions are compatible with your door.

Do smart or electronic lock cylinders require different measurements?

The basic measurement principles for cylinders (A, B, and C dimensions) are the same. However, check the manufacturer’s guidelines for specific requirements on cylinder length and type, especially for smart locks.