Cylinder locks are widely used across residential, commercial, and light industrial environments. They are valued for reliability, straightforward operation, and a replaceable core design that simplifies long-term maintenance.

Like any mechanical security component, cylinder locks can develop practical issues over time. Understanding how they work and how problems appear helps property owners and small businesses maintain secure, dependable access without unnecessary disruption.

This guide explains how cylinder locks function, outlines common issues, and provides practical solutions that support stable daily operations. For retail stores, offices, clinics, and shared workspaces, reliable cylinder locks also help maintain controlled access, staff accountability, and operational continuity.

Table of Contents

ToggleCylinder Lock Basics, What They Are and How They Work

What a Cylinder Lock Is and Why It’s Widely Used

A cylinder lock is a locking device that uses a cylindrical core to control locking and unlocking. It is commonly installed on doors in homes, offices, retail spaces, and utility areas.

Key characteristics include:

- Reliable mechanical performance

- Simple daily operation

- A replaceable lock cylinder without changing the full lock body

This design allows businesses to maintain consistent security while keeping repairs, upgrades, and key changes manageable over time.

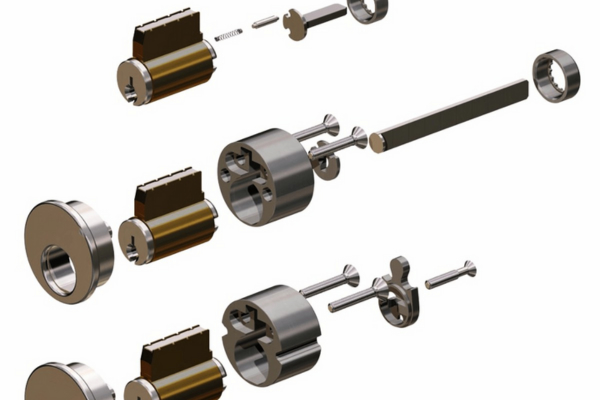

Key Parts Inside a Cylinder Lock

A standard cylinder lock relies on several internal components that work together to secure a door and support smooth operation.

- Lock cylinder, the central unit containing the keyway and pin system

- Pins and springs, pin stacks that control rotation and locking

- Plug, the rotating core that turns when pins align correctly

- Housing, the outer shell that protects internal components

- Latch or bolt, the part that extends or retracts to secure the door

Each component directly affects reliability, wear rates, and how often service or replacement may be required.

How a Cylinder Lock Operates in Daily Use

Most cylinder locks operate on the pin tumbler principle.

- The correct key is inserted into the cylinder

- The key’s cuts lift each pin stack to a precise height

- Pin separation points align with the shear line

- The plug rotates and moves the latch or bolt

If alignment is incorrect, the plug cannot rotate and the door remains locked. This simple mechanism is effective when manufacturing quality and installation are consistent.

Common Types of Cylinder Locks and Where They Are Used

Single vs Double Cylinder Locks

Single cylinder locks

These locks use a key on the exterior and a thumb turn or handle on the interior. They allow fast exit during emergencies and are widely used on office and retail entry doors. For small businesses, this design supports smooth daily movement without complicating access.

Double cylinder locks

These locks require a key on both sides of the door. They add protection against break-ins through nearby glass panels. In storefronts or offices with glass adjacent to doors, this option helps reduce risk when equipment or inventory is stored inside.

Keyed Alike and Master Key Systems

Keyed alike systems

Multiple locks operate with the same key, reducing the number of keys staff must manage. This approach suits small businesses with several doors and limited access requirements.

Master key systems

Individual keys open specific doors, while one master key opens all locks. Property managers and growing teams use this setup to balance security, accountability, and operational efficiency.

Common Cylinder Lock Problems and How to Fix Them

When Key Operation Becomes Difficult

Issue 1, the key is difficult to insert or turn

Possible causes:

- Dust or debris inside the cylinder

- Lack of lubrication

- Light corrosion

Solutions:

- Apply a dry graphite or silicone-based lock lubricant

- Insert and remove the key several times to distribute lubricant

- Avoid oil-based products such as WD-40, which attract dirt over time

Issue 2, the key breaks inside the lock

Solutions:

- If visible, remove the fragment with tweezers or needle-nose pliers

- If fully lodged, use a key extraction tool or a bent paperclip

- Clean the cylinder and inspect for remaining debris

Stiff operation is often an early sign of wear. Addressing it promptly helps prevent sudden lockouts during business hours.

When the Cylinder Stops Working Properly

Issue 3, the cylinder spins but the door does not unlock

Possible causes:

- A loose retaining screw

- A damaged cam or tailpiece

Solutions:

- Remove the lock and tighten the retaining screw

- Replace the cam or cylinder if damage is found

Issue 4, the cylinder feels loose or wobbly

Possible causes:

- Loose mounting screws

- Worn installation holes

Solutions:

- Remove trim and tighten fixing screws

- Replace worn hardware if stability cannot be restored

Repeated failures across multiple doors often indicate that upgrading cylinders is more practical than ongoing repairs. For businesses, unstable locks increase downtime, staff disruption, and security exposure.

Mechanical Lock Failures That Affect Security

Issue 5, the latch does not extend or catch properly

Possible causes:

- Misaligned strike plate

- Door sagging

- Worn latch mechanism

Solutions:

- Adjust the strike plate to align with the latch

- Tighten door hinges

- Replace worn latch components when needed

Issue 6, grinding or friction noise during operation

Possible causes:

- Lack of lubrication

- Foreign debris

- Internal spring wear

Solutions:

- Clean and lubricate moving parts

- Replace the cylinder if noise continues

Mechanical wear that affects smooth operation often signals reduced service life and increased maintenance risk.

Security Risks and Physical Damage

Issue 7, rust or corrosion, common in outdoor locks

Solutions:

- Clean external surfaces with rust remover

- Apply corrosion-resistant lubricant

- Replace severely corroded cylinders with weather-rated models

Issue 8, signs of forced entry or tampering

Solutions:

- Replace the lock immediately

- Do not continue using any lock with compromised security

Once physical integrity is compromised, continued use increases risk and undermines access control.

FAQ

Are cylinder locks secure and resistant to picking?

High-quality cylinder locks provide reliable protection when properly manufactured and installed. Security improves with anti-pick, anti-bump, and anti-drill features. For businesses, certified security cylinders help reduce tampering risk and maintain consistent access control.

If I lose a key, do I need to replace the entire lock?

Not always. Rekeying or replacing the cylinder is usually sufficient. This restores access control without changing the full lock body, helping businesses reduce cost, minimize downtime, and maintain existing door hardware.

How do I know when a cylinder lock needs replacement?

Replacement is recommended if the lock remains difficult to operate after lubrication, feels loose, shows visible damage, or shows signs of tampering. Repeated service issues often indicate that upgrading is more reliable than continued repairs.

Can I repair or replace a cylinder lock myself?

Basic cleaning and lubrication are suitable for DIY maintenance. Cylinder replacement requires correct sizing and alignment. For commercial or high-security doors, professional installation helps protect long-term performance and security integrity.

Is a single or double cylinder lock better?

Single cylinder locks support easy exit and suit most offices and retail spaces. Double cylinder locks add protection for doors with nearby glass. The better choice depends on door design, safety needs, and break-in risk.

How can I unstick a door lock cylinder?

Stiff operation is often caused by debris or lack of lubrication. Applying a dry lubricant and gently working the key can restore function. If resistance continues, internal wear may require cylinder replacement.

How to Maintain a Cylinder Lock for Reliable Performance

- Clean the keyway regularly using compressed air

- Lubricate every six to twelve months with a dry lubricant

- Avoid forcing the key when resistance appears

- Use weather-resistant cylinders for outdoor or humid environments

When maintenance no longer restores smooth operation or confidence in security, upgrading the cylinder becomes the more reliable long-term choice.

How to Choose or Upgrade the Right Cylinder Lock

For businesses, cylinder lock selection affects access control, risk exposure, and long-term operating costs.

- Assess the security importance of each door

- Choose cylinders with verified anti-pick, anti-bump, and anti-drill features

- Confirm size, standard, and door compatibility before purchase

- Select corrosion-resistant materials for outdoor or humid locations

Careful selection improves reliability while reducing future service needs.

Making Informed Decisions About Cylinder Lock Security

Cylinder locks remain a dependable foundation for mechanical security. Understanding how they work, how issues develop, and when upgrades make sense helps businesses maintain control without unnecessary complexity.

From a business perspective, cylinder locks should be evaluated as part of a broader access strategy, not as isolated hardware. Consistent performance, stable tolerances, and long-term availability matter as much as initial security features. Poorly manufactured cylinders often lead to frequent service calls, uneven key operation, and inconsistent access across doors. Over time, these issues create hidden operational costs.

EOS SECURE delivers precision-engineered mechanical and electronic lock cylinders backed by more than a decade of manufacturing expertise. Established in 2011, our factory operates under ISO9001 and ISO14001 certifications and meets international standards including EN1303 and SKG. With advanced Swiss-type CNC production and strict quality control, EOS SECURE supports both small-batch customization and large-scale supply. Explore EOS SECURE solutions to strengthen long-term security with confidence.