Table of Contents

ToggleWhy the Difference Matters for Business Security

Many people treat the words “lock” and “lock cylinder” as if they describe the same component. They do not. Each part plays a different role in how a door stays secure. When the two terms are mixed together, it becomes harder to choose hardware, compare products, or understand a door’s overall protection level.

For small businesses, this distinction affects daily access management and long-term security planning. Selecting the right combination of components can reduce service costs, simplify key control, and improve resistance to intrusion. This guide explains each part in clear terms and shows how they work together as a complete system.

What a Lock Is

A lock is the full mechanical or electronic assembly that secures a door, gate, cabinet, or other entry point. It creates the physical connection between the door and the frame, and it manages how the latch or bolt moves during use. The lock’s construction determines how well the door stands up to force, prying, or repeated daily activity.

Locks work with many types of credentials, including traditional keys, keypads, and electronic access systems. The lock body provides the structural strength that prevents unauthorized entry, which makes it a critical part of any security plan.

What a Lock Cylinder Does

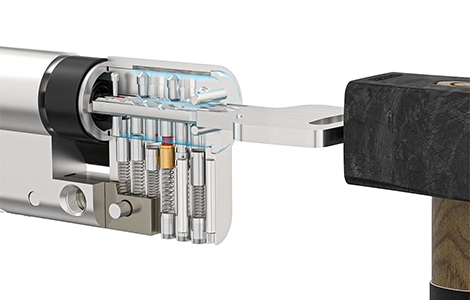

A lock cylinder is the removable core inside the lock body. The key is inserted into the cylinder. The internal components confirm whether the key is valid, and when the match is correct, the cylinder rotates and activates the lock.

Because the cylinder controls authorization, it is often upgraded more frequently than the lock body. Most cylinders can be replaced without removing the entire lock, which allows businesses to rekey a door or improve security with minimal downtime.

Common Lock Types for Commercial Use

Different lock types support different levels of security and convenience. The most common options include the following.

Deadbolts

Deadbolts extend a solid metal bolt into the frame to provide strong resistance against physical force. They are widely used on exterior doors in small offices and retail spaces. Single-cylinder models use a key outside and a thumb turn inside, while double-cylinder models require keys on both sides for added control.

Auto Slam Shut Locks

These locks secure the door automatically when it closes. They reduce the risk of an unlocked entry during busy hours, which is helpful for retail stores, service counters, and delivery areas.

Padlocks

Padlocks protect gates, storage units, cages, and equipment areas. They are available as keyed, combination, or electronic models. Their portability makes them useful for temporary or movable security needs.

Knob Locks

Knob locks place the locking mechanism inside the knob. They appear on interior doors but offer limited resistance to force, so they are not recommended for exterior use.

Lever Handle Locks

Lever handle locks operate like knob locks but use a lever for easier operation. They are common in offices and accessible facilities because they support smoother entry for users with limited hand strength.

How Lock Cylinders Work

The internal design of a cylinder determines how it identifies a key and how well it resists tampering.

Pin Tumbler Cylinders

Pin tumbler cylinders are the most common commercial design. They use springs and vertical pins that align with the cuts of a valid key. High-security versions use hardened steel pins and added protections that slow drilling attempts.

Disc Tumbler Cylinders

Disc tumbler cylinders rely on rotating discs rather than pins. When the key aligns the slots in each disc, the cylinder turns. They offer strong resistance to many traditional manipulation methods.

Wafer Tumbler Cylinders

Wafer cylinders use thin wafers instead of pins or discs. When each wafer reaches the correct height, the cylinder rotates. They appear in light-duty applications.

Cylinder Profiles

Cylinders also vary in shape. The lock body only accepts the correct profile, so compatibility matters. The most common profiles include European, round, and oval designs. Choosing the right profile ensures proper installation and consistent operation.

How Locks and Cylinders Work Together

A secure door relies on both components. Each contributes to a different part of the system.

The cylinder confirms whether the credential is authorized. The lock body delivers the physical strength that resists force. When one component is weak, the entire system becomes vulnerable.

System Balance

Security improves when the lock body and cylinder offer similar levels of protection. A premium cylinder installed in a weak lock body can still fail under pressure. A durable lock body paired with a basic cylinder remains at risk of picking or bumping. Balanced hardware creates stronger and more reliable defense.

Upgrade Flexibility

Many cylinders can be replaced without changing the entire lock. This provides important advantages for small businesses.

- Faster rekeying after staffing changes

- Lower installation costs

- Minimal operational disruption

- Improved protection through targeted upgrades

As intrusion methods evolve, the ability to upgrade only the cylinder helps maintain long-term security without replacing complete hardware sets.

Why Both Components Matter

Security

The lock delivers physical strength and impact resistance. The cylinder protects against unauthorized key use and manipulation. Both are required for comprehensive protection.

Convenience

A well-matched system supports smooth operation throughout the day. This helps prevent jamming, misalignment, or incomplete locking.

Versatility

Different combinations of locks and cylinders allow businesses to tailor protection for offices, storefronts, warehouses, and mixed-use facilities.

Maintainability

Modular designs make it easier to service or improve the system. This reduces long-term costs and allows security to adapt as business needs change.

Frequently Asked Questions

Q1. What is the main difference between a lock and a lock cylinder?

A lock is the full mechanism that secures the door. The cylinder is the internal component that confirms whether the key is valid. Both parts must work together to deliver complete security.

Q2. Are all lock cylinders interchangeable?

No. Cylinders must match the lock body and profile to fit correctly. Some designs are replaceable and others are fixed, so compatibility depends on the hardware already installed.

Q3. How do I choose the right lock cylinder?

Review your security needs, door type, and existing lock. High-security cylinders with anti-drill, anti-pick, and anti-snap features offer stronger protection for exterior and high-traffic areas.

Q4. Can I upgrade only the cylinder to improve security?

Yes. Replacing the cylinder is an efficient way to improve protection without changing the entire lock. It supports faster rekeying and reduces downtime during installation.

Q5. How should a lock cylinder be maintained?

Keep the keyway free of dust, use a dry lubricant, and avoid excessive force when turning the key. Proper door alignment helps the cylinder operate smoothly and reduces long-term wear.

Q6. What makes a high-security cylinder more effective?

High-security cylinders use reinforced materials and advanced internal components that resist drilling, picking, snapping, and key bumping. These features slow intrusion attempts and strengthen overall performance.

Q7. Is upgrading only the cylinder enough?

Not always. A weak lock body can still fail under force. The best results come from pairing a strong cylinder with a durable lock so both parts offer similar levels of protection.

Build Stronger Security With EOS SECURE

EOS SECURE delivers precision-engineered mechanical and electronic lock cylinders backed by more than a decade of manufacturing expertise. Our factory operates under ISO9001 and ISO14001 certifications, and our products meet international standards including EN1303 and SKG. With an advanced production line that includes Swiss-type CNC lathes and integrated machining centers, we support both customized orders and large-scale manufacturing. EOS SECURE provides consistent quality, dependable performance, and responsive technical support. Strengthen your business security with solutions built for long-term reliability.